Bella Core Vertical Surfaces Provide Ease of Use, Durability, Cost and Look Customers Want

There is a new solution in the marketplace for mobile home bathroom walls, and it involves grout-free vertical surfaces for easy installation and maintenance, as well as a natural look.

Bella Core vertical surfaces come in a cost-efficient poly (PVC) representation of stone, and in natural thin-stone as well.

Anthony Tesvich is in outside sales with Bella Core. He said the poly product is made for manufactured homes even though it has applications in other sectors and industries as well.

“If the corner of the wall is not perfect or the wall is not flat, there usually is a problem with what’s traditionally been done in the market,” Tesvich said. “Because of the way this system is built for the industry, the Bella Core poly surfacing provides the play needed to fit the space and look the way you want it.”

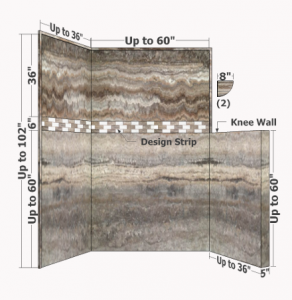

Construction of the Bella Core Grout-Free Vertical Surfaces

I-beam construction of the panels provides a rigidity for a shower wall that stays. And the panels that intermesh rather than abut each other create a solid construction that will endure heavy use.

Tesvich said he has been touring manufactured housing factories and coaching retailers and their customers on the merits of the grout-free vertical surfaces, both in poly and natural thin-stone.

He said the reception in the market has been a warm one. This is because professional installers and DIY weekenders alike have experienced the frustration of working with tile and grout systems, which are difficult to install, or the cheaper alternative which damages easily and tends to slump. The Bella Core products create a middle ground for cost and quality that customers appreciate.

“We’re going to go show them the best thing they’ve never seen, and the reception is phenomenal,” Tesvich said. “This is what people are looking for to finish their bathrooms.

“We are looking to bring manufacturers into this new era of bathroom finish and appeal,” he said. “There is a style and design to a bathroom that’s finished this way that really raises the value of the entire home.”

Bella Core Was Made for Manufactured Housing

The Bella Core Poly system in particular works well because it’s lightweight and sealed with silicon. This type of construction will hold up dramatically better than tile and grout in a home that’s being transported and sited. While the thin-stone is heavier, it’s no less durable.

“Once the prep work is done, it’s somewhat like peel and stick,” Tesvich said of the Bella Core products. “That’s what the product does. It rolls up onto the wall. And it is real marble, real travertine that is being used. And, of course, the Poly system is a fabricated representation of this look.”

Someone with maintenance experience can install a new Bella Core system in two hours, Tesvich said. And the finished product repels water more readily than other systems, and is easy to wipe down.

If you save expenses on wall surfaces, resources can to a new pedestal sink or spa tub.

What Can You Expect to Spend on Grout-Free Vertical Surfaces?

The thin-stone product costs about 15 to 20 percent more than ceramic tile installation. However, it comes out about 15 percent less than if you were installing natural stone tiles. The Poly product costs about 12 percent more than fiberglass, which is often used. But the value over time far outweighs the up-front cost. And the poly is about 40 percent less than the acrylic solution, which often show air bubbles that create wear.